Surmounting Key Scientific Challenges in Food and Beverage Innovation with Real-time Analytics

Modern food and beverage innovation requires an in-depth understanding of how individual components behave under demanding processing, storage, and packaging conditions. From protein aggregation and vitamin and flavor degradation during pasteurization to the change in solubility of natural, high-intensity sweeteners, each avenue of research brings its own complexities. Below is an outline of key scientific and technological hurdles facing R&D teams and how advanced, real-time analytics can help overcome them.

Navigating Pasteurization Complexities

Thermal exposure remains a cornerstone of food safety and extended shelf life. Subjecting proteins, flavors, and other labile compounds to heat can result in undesired changes like aggregation and degradation that can compromise end-product quality. Scientific insights into the stability of ingredients and the kinetics of heat-induced modifications are essential for optimizing pasteurization protocols without sacrificing nutritional or sensory properties.

Maintaining Protein Functionality in Functional Beverages

Protein-based beverages, which are often enriched with whey, casein, and associated peptides or other bioactive ingredients, must retain both nutritional and sensory appeal. Even slight changes in pH, temperature, or ionic strength can lead to protein precipitation, causing undesirable turbidity and mouthfeel. Real-time monitoring at the molecular level allows researchers to detect the onset of aggregation and adjust formulations before scaling up to production, which is essential during the early stages of food and beverage innovation.

Addressing Natural Sweetener Solubility and Flavor Profiles

Stevia-derived sweeteners (rebaudiosides) are popular for their natural, zero-calorie attributes. However, limited solubility and potential off-notes like bitterness continue to pose challenges during food and beverage innovation projects. Maintaining consistent flavor and solubility requires a precise understanding of how sweeteners and other flavor compounds behave in synergy under processing and storage conditions.

Ensuring Flavor Stability during Food and Beverage Innovation

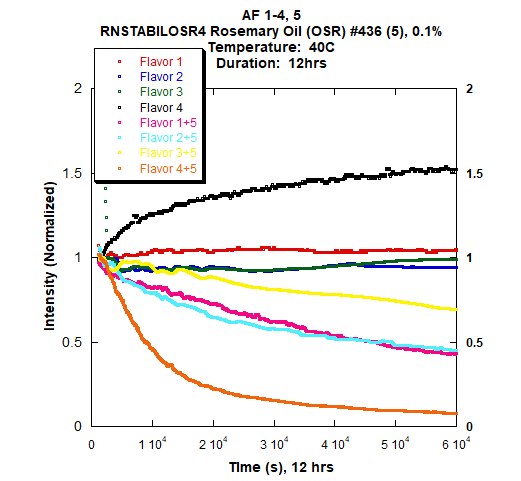

Flavor degradation is a pervasive issue in the food and beverage industry—particularly for natural, citrus-derived flavors containing limonene, which can lose potency or develop off-aromas during processing and storage. Figure 1 illustrates the ability of static light scattering (SLS) to monitor the stability of citrus flavoring temporally in the presence and absence of a stabilizing agent under accelerated conditions (40°C). Four citrus flavors were analyzed with and without rosemary oil at 40°C for 12 hours.

Flavors 1, 2 and 3 remained stable without the addition of rosemary oil. However, flavor 4 was unstable throughout the experiment, as evidenced by an increase in scattering intensity (increase in molecular weight average). Counterintuitively, the addition of rosemary oil resulted in instability for all four flavors. This data confirms the importance of analyzing the effect of stabilizing agents on flavor stability during development and permits the optimization of a flavor/stabilizing system.

Mitigating the Destabilizing Effects of Dissolved Oxygen

Dissolved oxygen (DO) fuels the degradation of flavor, nutrients, and packaging (aluminum cans, in particular). R&D teams generally employ nitrogen purging or controlled heating to limit DO, but these methods must be continuously validated. The ability to reconcile DO content with flavor and ingredient stability is critical for successfully upscaling production and prolonging shelf-life.

Prolonging Shelf Life and Vitamin Stability

Beyond flavor and sweetness, many formulations incorporate vitamins and micronutrients that are prone to degradation when exposed to heat, light, or oxygen. A detailed analysis on how these components respond to stressors provides data-driven pathways for extending shelf-life. By defining the kinetics of vitamin stability, teams can make informed choices about packaging, process conditions, and antioxidant use to preserve nutrient content.

How Real-Time Analytics with ARGEN Solve These Challenges

While the aforementioned issues demand highly specialized research, they also share a common need: continuous, multi-parameter feedback to guide decision-making. ARGEN, developed by Yokogawa Fluence Analytics, delivers exactly that, offering a comprehensive, real-time view of ingredient interactions and stability under varying conditions.

1) Continuous Monitoring of Protein and Ingredient Stability

- By quantifying and qualifying protein and nutrient instability in situ, ARGEN enables R&D teams to refine pasteurization and formulation variables, preserving key functional and nutritional properties.

2) Solubility Profiling for Complex Formulations

- ARGEN pinpoints the precise conditions under which sweeteners, flavor enhancers, and other ingredients dissolve or precipitate, helping maintain consistent flavor and appearance across production runs.

3) Flavor Stabilization

- As shown in Figure 1 for citrus flavor compounds, real-time data exposes when and how flavor components degrade in the presence of stabilizing agents. This transparency empowers scientists to optimize stabilizer usage and reduce product failures due to off-flavors.

4) Dissolved Oxygen Management

- ARGEN validates whether nitrogen purging or degassing steps are effectively curtailing oxidation, especially crucial in nutrient-fortified drinks.

5) Accelerated Shelf-Life Studies

- By simulating real-world conditions (heat, pH, oxygen levels) at a small scale, ARGEN allows you to project shelf life with greater precision and minimize costly reformulations late in the development cycle.

Advancing Your R&D with Precision and Confidence

In a marketplace defined by nutritional efficacy, flavor distinction, and cost-effectiveness, rigorous scientific validation can turn promising concepts into commercial successes. ARGEN’s real-time analytical approach offers the depth, reproducibility, and actionable insight necessary to tackle your most pressing R&D challenges.

If you’re seeking to optimize pasteurization outcomes, bolster flavor stability, or enhance vitamin shelf life, we invite you to connect with us. Let’s explore how ARGEN can supplement your research, guiding you toward data-driven breakthroughs in your next generation of food and beverage products.

Connect with Yokogawa Fluence Analytics Today!