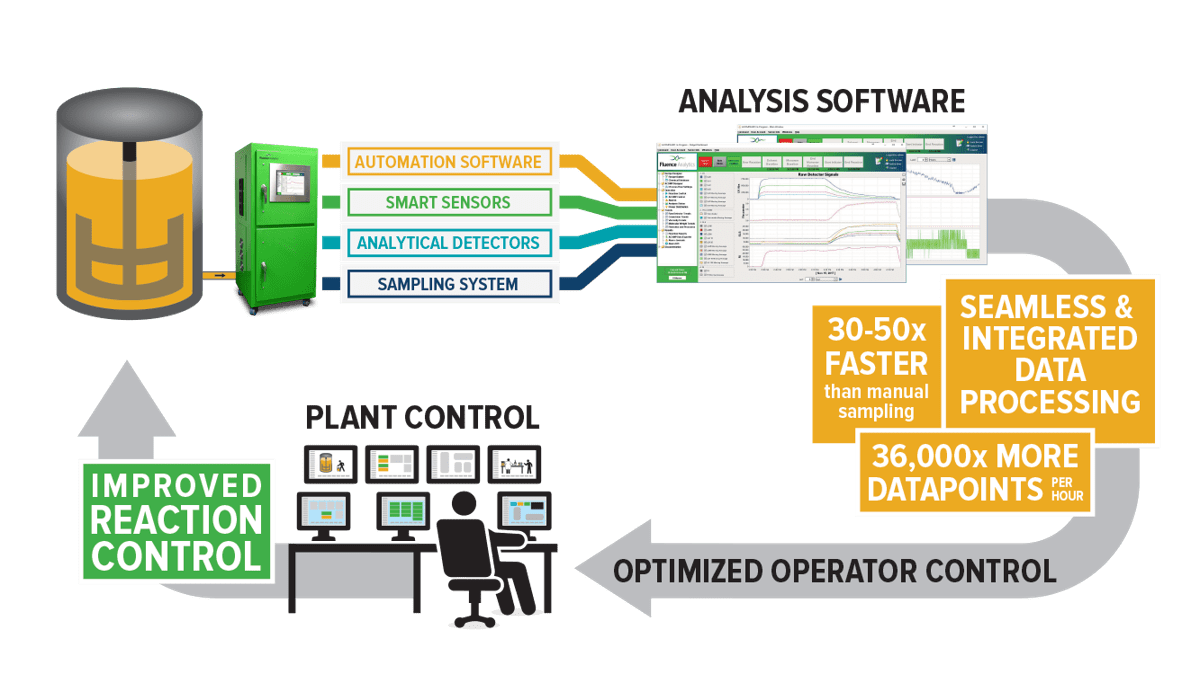

ACOMP is a real-time monitoring system that generates continuous measurements on critical polymer properties during production via continuous sampling and measurement of the reactor. By providing these real-time insights, Yokogawa Fluence Analytics is disrupting the historical manner in which polymers used in paint and coating applications are synthesized.

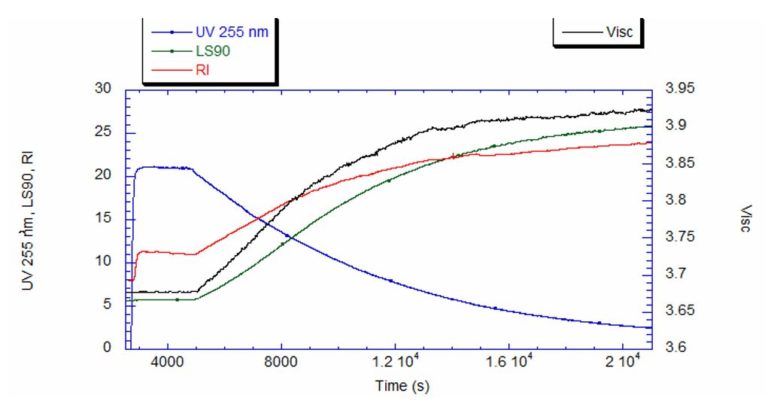

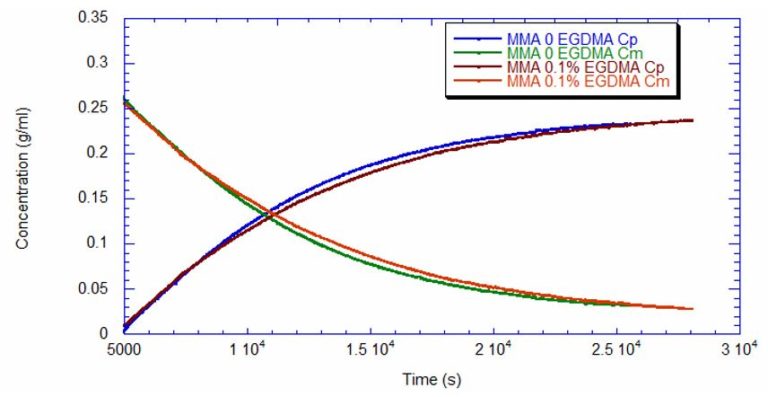

The smart manufacturing system produces a highly conditioned sample stream on which multiple analytical measurements are continuously made. These measurements yield data on conversion, kinetics, residual monomers, molecular weight, viscosity and other critical parameters. These polymer analytics have contributed to optimized process control and reduced cycle times, which have decreased overall costs for customers. With enhanced data and control, customers can also scale up faster while accelerating the next generation of products to market.

Increase Polymer Yield, Quality and Consistency

Optimize Process Control

Reduce Cycle Times, VOCs and Material Usage

Detect Anomalies During Production

During production, polymer properties are determined by the traits of the molecules themselves. In paint and coating applications, viscosity, molecular weight and composition affect certain end product qualities, including strength, brittleness, solubility and others. Monitoring these polymer attributes during synthesis is the first step in controlling the manufacturing processes of polymers used in paint and coating applications.

ACOMP has successfully monitored many polymer chemistries that are commonly used in such applications. These include acrylic, alkyd, epoxy, polyurethane, methacrylate, acrylate and others. Below is a link to an application note where ACOMP successfully monitored the solution polymerization of methyl methacrylate (MMA) in the presence and absence of crosslinker.