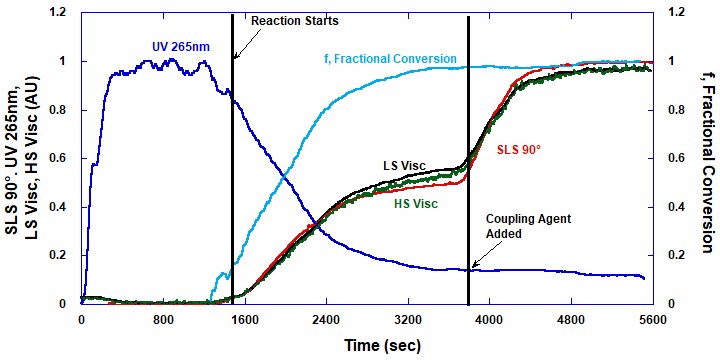

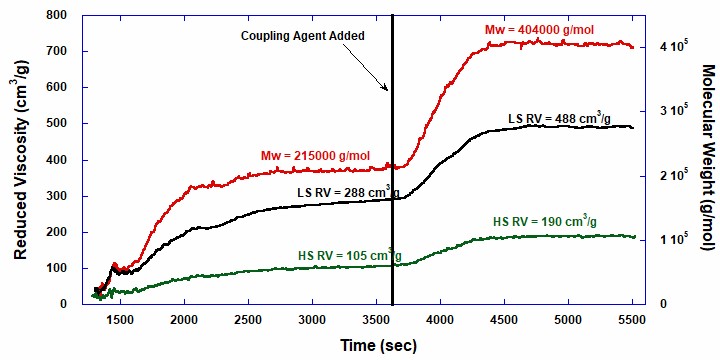

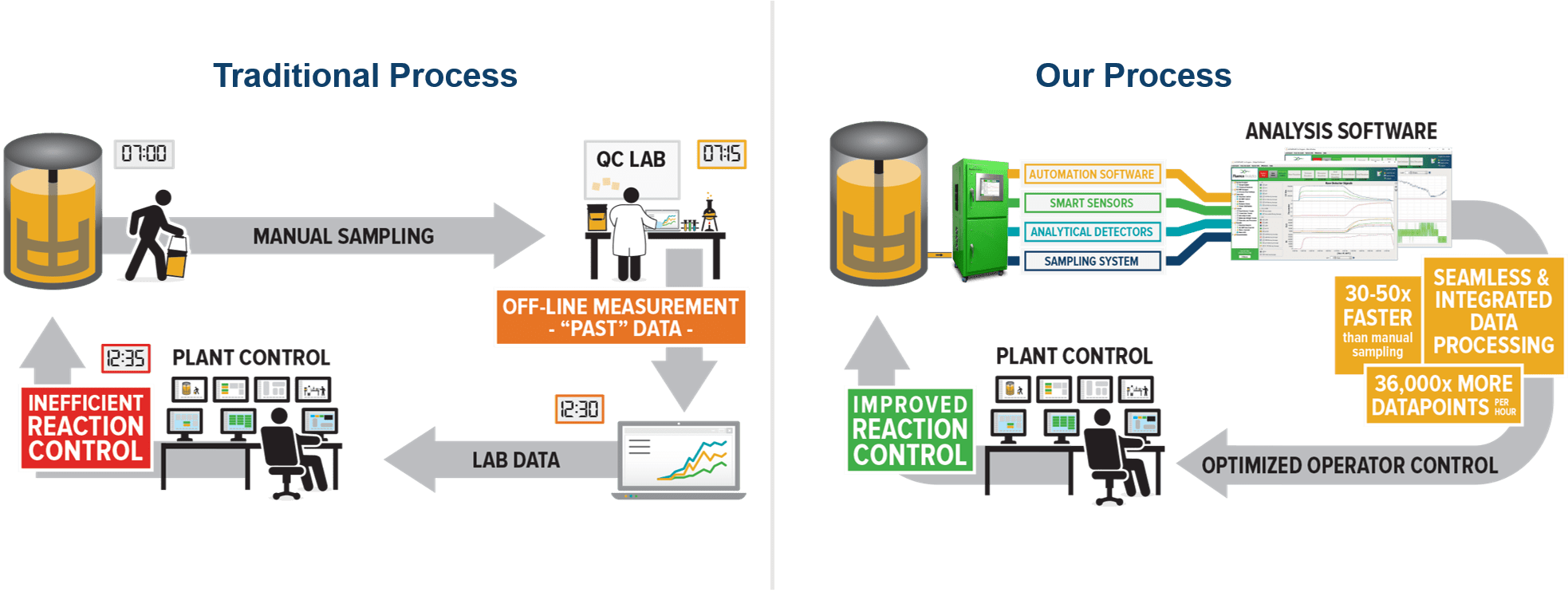

Historically, companies produce polymers for elastomer applications without monitoring what happens inside the reactor. These manufacturers employ chromatography measurements once the reaction is complete or intermittently during production. Thus, there is a lack of real-time data which results in reactions running longer than required to mitigate against off-spec polymer batches. Such a process consumes more energy, operator time and equipment availability than is required. Conversely, ACOMP, an innovative product available from Yokogawa Fluence Analytics, yields continuous, real-time measurements on critical polymer properties during production.

Increase Polymer Yield, Quality and Consistency

Optimize Process Control

Reduce Cycle Times, VOCs and Material Usage

Detect Anomalies During Production

ACOMP’s real-time polymer analytics have contributed to optimized process control and reduced cycle times, which have decreased overall costs for customers. With enhanced data and control, customers can also scale up faster while accelerating the next generation of products to market.

ACOMP has successfully monitored many polymer chemistries that are commonly used in elastomer applications. These include EPDM, Styrene Butadiene Rubber (SBR), Solution Styrene Butadiene Rubber (SSBR), Emulsion Styrene Butadiene Rubber (ESBR), Styrene Isoprene Rubber (SIR), Acrylonitrile Butadiene Styrene (ABS), Nitrile Butadiene Rubber (NBR), Butyl Rubber, Acrylonitrile styrene acrylate (ASA) and others.