Why this matters

ACOMP performs a continuous sampling of reactor contents while monitoring critical polymer properties, including molecular weight, viscosity, monomer conversion, and concentrations in real time. Using ACOMP in an industrial environment allows for improved polymer quality control of production processes and material properties. Commonly observed benefits include higher yields, reduced off-spec materials, and tighter product specifications, which ensures a more streamlined process and optimal performance from end-product materials. These benefits are of equal or even greater value during process scale-up.

Overview

Reproducibility and product quality control are two major factors in routine production and scale-up of existing or new polymer products. Variations in outcomes during scale-up efforts originate from the inherent nature of the reaction (kinetics) and the problems specific to scaling up a process (diffusion, lack of homogeneity of reaction conditions, presence of oxygen or other impurities, etc.).

When conducting polymerization reactions at the pilot plant or industrial scale, oftentimes producers are unable to determine product quality (adherence to specification, consistency) until hours after the reaction is complete. Although engineers attempt to minimize process and product quality deviations, reliance on off-line analysis inevitably results in a significant delay time, leading to poor visibility into the reaction process and suboptimal control.

ACOMP provides real-time, online analysis of polymerization reactions. This is achieved by continuous sample extraction and characterization as the reaction unfolds, providing users with immediate insight into reaction kinetics and the macromolecular polymer properties of molecular weight, reduced viscosity, and in some cases conversion and composition. This technical note describes the advantages of using ACOMP to optimize process control and product quality through online, real-time analysis.

Polymer Quality Control in Acrylamide Reactions

As shown in Table 1, a total of five free radical acrylamide reactions were run in a batch 1-liter reactor using 1.5% KPS (potassium persulfate), a common free radical initiator.

| Run # | Monomer Mass | Solution Volume | KPS Mass | Time to 65˚C | N2 Pre-Purge Time |

| 1 | 15.005 g | 482 ml | 0.224 g | 24 min | 41 min |

| 2 | 15.000 g | 480 ml | 0.224 g | 40 min | 62 min |

| 3 | 15.001 g | 479 ml | 0.224 g | 39 min | 55 min |

| 4 | 14.998 g | 481 ml | 0.224 g | 38 min | 56 min |

| 5 | 15.000 g | 481 ml | 0.225 g | 60 min | 79 min |

Table 1: Polyacrylamide reaction condition table (1.5wt% KPS initiator)

These runs nominally followed the same product recipe but experienced variations in conditions as shown in the right two columns in Table 1. The ACOMP results clearly demonstrate the resulting discrepancies in product properties from reaction to reaction. It should be noted that without the continuous online characterization provided by ACOMP, it would be very difficult to evaluate the impact of the different reaction conditions, as an operator would have to take multiple samples during the reaction. Even if such samples were taken, the results using typical lab analysis techniques (eg. GPC) would incur a significant delay time.

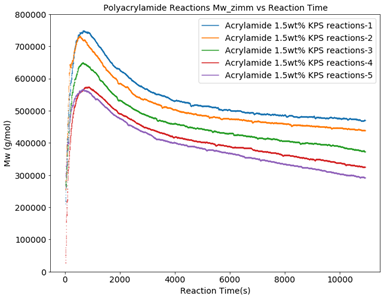

Figure 1 shows the results of weight-average molecular weight (Mw) and displays a significant discrepancy from reaction to reaction. A good example is the comparison between Run 1 (dark blue) and Run 5 (purple). Run 1 had a shorter nitrogen pre-purging time and a shorter heating time, which may have resulted in higher oxygen content in the reactor. This yields a higher monomer to initiator ratio and, consequently, a higher molecular weight. There are other possible factors that could affect the result such as diffusion, reactor homogenization, initiator efficiency, etc. The explanation for differences between the curves could be further studied using multivariate techniques such as designed experiments at different temperatures and purge times. A better understanding of these factors would be extremely helpful if it is desired to have a tight product quality specification based on a fundamental polymer property like molecular weight.

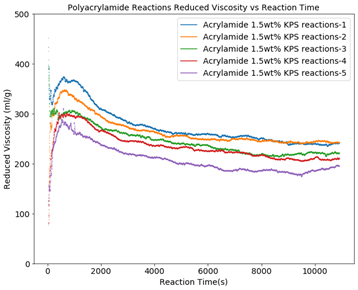

Reduced viscosity is correlated with viscosity-average molecular weight, and it is also an important property that often reveals a material’s structural information. Generally, a lower molecular weight polymer has a lower reduced viscosity, but reduced viscosity also includes effects of branching, cross-linking, and sometimes composition. In this case, as shown in Figure 2, the reduced viscosities of the different batch reactions display roughly the same trend and order as the molecular weights shown in Figure 1.

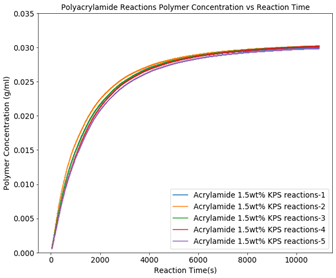

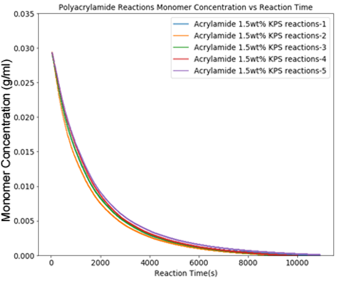

For the acrylamide homopolymer system, in addition to Mw and reduced viscosity, ACOMP can monitor monomer and polymer concentration in real time during the polymerizations. As shown in Table 2, there are noticeable differences in time to conversion at both 10% and 90% among the five runs.

| Run # | Time to 10% Conversion (sec) | Time to 90% Conversion (sec) |

|

1 |

170 | 3788 |

| 2 | 152 | 3975 |

| 3 | 167 | 4007 |

| 4 | 192 | 4142 |

| 5 | 197 | 4419 |

Table 2: Time to 10% and 90% monomer conversion for reactions at 1.5wt% KPS

When graphed, as in Figures 3 and 4, these differences seem more subtle than the differences in polymer properties. Even when the final monomer and polymer concentrations (at the 10000-second mark) are nearly identical, the measured Mw from the five runs has a standard deviation of 80k g/mol (roughly 20%) and for viscosity it is 34 ml/g (around 15%). These variations are significant enough to affect processing and/or end use properties of the resulting polymers. Therefore, it is very useful to understand this behavior from the standpoint of quality control. The ACOMP system can measure properties like weight-average molecular weight or reduced viscosity in real time, which is a huge benefit vs. “flying blind” and only understanding the outcome after the reaction is complete.

Conclusion

Wide deviations between individual batches are common both during production and scale-up of free radical reactions, such as the polymerization of acrylamide. With the benefit of an online, real-time analysis provided by ACOMP, plant operators can take corrective actions to change polymer quality control parameters or even halt the reaction if the product properties are deviating too much.

Similarly, chemists and process design engineers using ACOMP can leverage this real-time visibility into the process to better understand the factors affecting the polymerization’s kinetics and the properties of the polymer product. This ACOMP advantage can significantly accelerate and improve scale-up processes. For more information on acrylamide polymerizations, download the polyacrylamide technical note.